Robotics and automation systems have helped businesses keep up with growing demands while remaining cost-efficient. These advances in technology also assist in smooth order picking, real-time tracking, and many other processes. Automated sorting systems are becoming more affordable and available in various versatile configurations to accommodate single piece picking in part-to-picker and picker-to-part configurations. Additionally, high-speed automation is leading to technology that can load and unload trucks at the pallet and carton level. Over the next decade, the material handling industry should expect to become more immersed in automated processes.

While Topper Industrial is considered the pioneer in North American Fork Truck Free initiatives, delivery carts are being tugged by more and more mobile robots and Automated Guided Vehicles (AGVs).

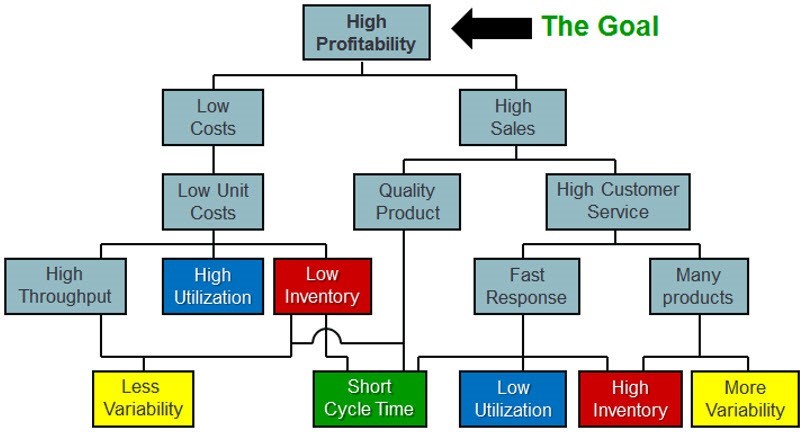

Achieving profitability is an obvious goal for all companies. The path to high profitability is greatly influenced in the best-practices of automated Fork Truck Free delivery carts by Topper Industrial. With robotics and automation solutions integrated on the plant floor, the factors of variability, cycle time, inventory control, and production elements of productivity and throughput are dramatically impacted.

Self-driving forklifts, tuggers, and mobile robots provide automation and robotics transform warehouse work

Capable of autonomously maneuvering around warehouses, picking up heavy loads, taking them where they need to go, and then unloading them is now possible without any human danger needed. When the cycle time is reduced, the OEE (Overall Equipment Effectiveness) will increase – more product is produced for less resource.

Topper Industrial carts tugged by autonomous vehicles specialize in helping human workers haul extremely heavy loads of materials around the facility floor, making the whole system more efficient. This additional layer of automation executes hands-free load exchange from pickup to drop-off. A robot can approach a pallet, lift it up quickly and carefully, and drive off to the next point. This end-to-end automation solution optimizes warehouse operations.

Compared to the older AGVs that have been used in similar facilities for more than a decade, self-driving forklifts do not require any changes to a facility’s infrastructure for immediate deployment and linked to Topper Industrial carts. Each vehicle operates using recognition algorithms, instead of the wires, lasers, magnets, or tape commonly used by AGVs.

About Topper Industrial

For more than twenty years, Topper Industrial, (www.topperindustrial.com) based just outside of Milwaukee, WI, has been a leader in the material handling equipment industry. The company’s product roster features industrial carts, conveyors, lifts, lifts & tilts, shipping racks, containers, casters, and cart components. From mother-daughter carts to quad steer carts to tilt carts and rotate carts, Topper’s material handling solutions make delivering material line side more effective through more efficient practices. Topper Industrial has a team of experienced professional experts able to assess and provide the right product for all material handling equipment requirements.

Topper Industrial is a proud member of MHI. Follow on Twitter @TopperInd or on LinkedIn.