By TR Cutler

Original Article HERE.

The process of switching from fork truck environments to fork truck free environments has become an essential strategy during COVID-19. The return on investment (ROI) for industrial carts is achieved through the process change itself. With social distancing here to stay, carts are safer when equipped with quality components that require little or no maintenance and repairs. Top tier delivery carts are more reliable for delivery than fork trucks and require reduced human interaction. As fork truck free manufacturing plants grow, Lean Manufacturing principles are adopted.

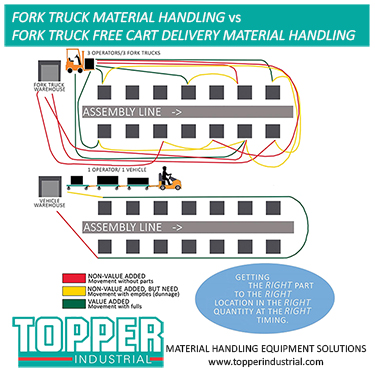

The illustration above demonstrates how fork truck free utilizes Lean Manufacturing principles; defined by the practice of reducing and eliminating non-value-added activity.

Delivery cart systems are immediately transforming the material movement process and gets the right material in the right quantity to the right place at the right time. Nowhere is this more obvious than during COVID-19. From large footprint distribution centers to manufacturers with cellular manufacturing operations, having product (raw materials or finished goods) delivered directly to a workstation or packing location is most efficient.

Cart delivery and Lean Manufacturing methods during COVID-19 are speeding factory production, improving safety, and throughput.

Topper Industrial specializes in the design and building of custom delivery carts for material handling. Ed Brown, founder of Topper, holds many patents for components and the mechanics of custom-designed carts. Industrial carts can be pushed, pulled in a train, and are able to turn in tight spaces. They can also link to complimentary vehicles like tuggers and automated guided vehicles (AGVs).

Fork truck free flexibility critical during COVID-19 Unlike other industrial cart manufacturers with standard product lines, flexibility is critical now as workflow, workstations, and product delivery are being modified daily to ensure the best ergonomic and safest social distancing is respected. Catering to these variables during the pandemic (and for the foreseeable future) recognizes that not all material processes are the same and ever changing. Topper Industrial holds a US Patent No. 10,093,334. The patent covers Topper’s Walk Through, Wheels on the Ground Mother-Daughter Cart System. This Mother-Daughter Cart System is an industrial cart system that consists of one large mother cart and two or more, smaller daughter carts. The daughter carts are designed to fit within the mother cart’s framework. Once inside, the daughter carts are locked into the mother cart.

Most other systems have the daughter carts load from one side only. Daughter carts will be pushed up into a ramp on the mother cart for transport. Daughter carts are able to be locked into the frame with wheels on the ground for transport and the operator is able to utilize the cart from both sides with a unique ability to push the carts all the way through the frame. This way, the mother cart and daughter carts are able to be tugged as one.

Ed Brown explained that the differentiation of these carts is found in the simplicity, functionality, maintenance, and overall operation. This is why the train of carts is towed by a tugger tractor and can make smooth, tight turns that are crucial in a factory with narrow aisles. At a time when fewer people can be on the plant floor making repetitive runs with fork trucks, cart delivery is both a viable and efficient alternative.

About the author: TR Cutler is the President and CEO of Fort Lauderdale, Florida-based, TR Cutler, Inc., celebrating its 21st year. Cutler is the founder of the Manufacturing Media Consortium including more than 8000 journalists, editors, and economists writing about trends in manufacturing, industry, material handling, and process improvement. Cutler authors more than 1000 feature articles annually regarding the manufacturing sector. Contact Cutler at trcutler@trcutlerinc.com

About Topper Industrial: Topper Industrial has a great team of people working hard each day to create the most reliable and innovative material handling products for our customers. Combined with over 40 years of experience in the material handling industry, Topper’s team of highly skilled engineers, designers and skilled workers is especially equipped to design and build Industrial Carts (Mother / Daughter Cart Systems, Quad Steer Carts or Tracking Carts, Specialized Delivery Carts, Transfer Carts with Roller Deck, Static Carts, Rotation Carts, Tilt Carts or Kitting Carts), Industrial Cart Components (Cart Parts Department), Industrial Containers (Corrugated Containers), Pallets, Lift/Tilt Systems, Racking and Tube & Joint. Topper is very proud of the dedication each and every team member has for developing quality products for ever changing needs across the supply chain.

Topper’s team is eager to help create solutions for every customer’s material flow requirements. All customers quickly become part of the extended Topper family. Contact us today at sales@topperindustrial.com.

“Keeping your material in motion.”