In just two weeks MODEX 2018 in Atlanta, Georgia materials handling professionals will share the MHI event with more than 30,000 supply chain, operations, and efficiency experts. Driven by innovation and the demand to squeeze more profits out of product and labor, a variety of new solutions, technologies, and best-practices will be explored.

Dave Blanchard reviewed in IndustryWeek that inventory takes on a lot of different identities within a manufacturing company. An accountant sees inventory as an asset, a controller sees it as a liability, a production supervisor considers it a safety net, while a materials manager finds it a tightrope. One common aspect to inventory, though, is that everybody agrees that holding it can be costly. Reducing inventory is a frequent outcome of moving to a fork truck free operation.

Lean manufacturing principles require elimination of waste and inventory reduction is a great place to start. At MODEX 2018 an educational seminar by Topper Industrial (http://bit.ly/2ib2n1V) will review some of the areas where inventory reduction coincides with FTF initiatives.

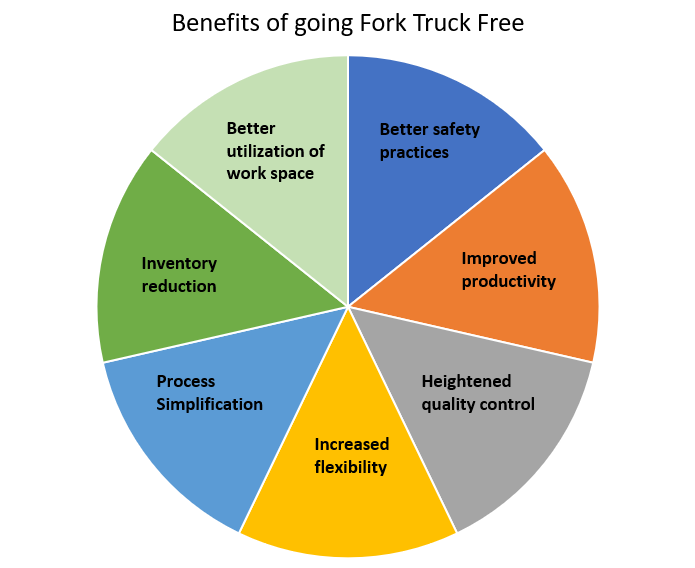

Some of the obvious metrics and protocols include reducing demand variability, improving forecast accuracy, re-examining service levels, and addressing capacity issues. The Fork Truck Free (FTF) environment often results in reduced order sizes, reduced manufacturing lot sizes, and reduced supplier and manufacturing lead times.

Having carts deliver product to a production line improves supply reliability by reconfiguring the supply chain.

A business that finds itself carrying an excess of inventory over the course of the year will find awful year-end financial results. Carrying high item counts in the supply chain results in a reduction in available cash flow and incurs high carrying costs for storing inventory items that do not necessarily need to be in the warehouse.

Inventory reduction and cost containment strategies should be a primary planning key performance indicator for all distribution and manufacturing companies; inventory reduction planning is the process by which inventory is reduced to free up working capital and prevent over-stocked items from becoming obsolete over a specific period of time. Proper planning and more intelligent procurement processes can help planners avoid these costly mistakes.

For further assistance and inquiries on Topper Industrial Material Handling Solutions, please contact sales@topperindustrial.com or visit www.topperindustrial.com.