Top Ten Benefits of Fork Truck Free with One Piece Flow and Small Lot: Delivery Improves Safety

- Improves safety by reducing motion, handling, and forklift movement

- Improves quality by first defecting defects instead of creating a bad batch

- Improves flexibility by shortening lead-times through processes (connected processes, smaller lot sizes)

- Improves scalability by making equipment that is efficient with smaller lot sizes.

- Reduces inventory by connecting processes and reducing lot sizes through quick changeover

- Improves productivity by working on one thing at a time and cutting out wasted motion

- Simplifies material replenishment by making the speed of material consumption steady and paced to a takt time

- Frees up floor space by opening space used for inventory

- Makes kaizen take root by exposing hidden problems and making them more visible

- Improves morale by promoting cross-training and skill enhancement, as well as identifying and solving problems more quickly and reducing frustration

Fork Truck Free Benefit: Improves safety.

According to insurance studies, a leading cause of workplace injuries is overexertion. According to a study from the National Safety Council, overexertion costs employers $13.4 billion a year, making it one of the top three costliest and disabling work-related injuries in the United States. In addition, overexertion causes fatigue, which results in less productive employees, increased quality errors, and more accidents.

Controlling Overexertion Injuries Statistics show that overexertion injuries can happen to any worker, at any age, and in any work situation. There are effective measures to successfully reduce the incidence and severity of overexertion injuries:

Optimize storage practices. In many cases, overexertion injuries can be prevented by storing heavier, manually-lifted parts in the lifting “power zone” between the knees and the shoulders. A great first step for many organizations is to simply raise the storage height of heavier parts to waist level, where equipment can be slid directly onto a cart and pushed to the desired location.

Use material-handling aids. The cost of a back-injury averages more than $40,000 according to the U.S. Department of Labor, which determined that there were 4.6 injuries per 100 fulltime employees in the workplace. Injured employees required an average of 19 therapy visits (Worker’s Compensation Research Institute). The average number of work days lost to work injuries was nine days. Sprains or strains accounted for 40 percent of the injuries. A work-related injury resulted in an average loss of approximately $38,000 including wages, productivity loss, and medical expenses. Furthermore, the National Safety Council documented that the longer manufacturers wait to treat worker’s compensation injuries, the greater the cost.

Use accident investigation as a learning tool. Rather than scolding employees to be more careful when lifting heavy objects, conduct a root cause analysis of each injury. Finding a permanent corrective action, such as going Fork Truck Free, is much more effective than simply telling employees to be careful.

Controlling overexertion injuries goes beyond focusing on compliance alone and should be incorporated into all components of an injury management program. It will help control claim costs, improve productivity, and provide a safer work environment for employees.

Smaller Lot Sizes and Fork Truck Free Reducing Injury and Fatalities

Lifting heavy containers and moving large pallets of materials are reduced when lot sizes are smaller. The reduction of just these two activities creates a statistically significant reduction in injuries.

Forklift fatality is common. OSHA statistics indicate that there are roughly 85 forklift fatalities and 34,900 serious injuries each year, with 42 percent of the forklift fatalities from the operator’s being crushed by a tipping vehicle. With fewer or no forklifts, manufacturers and distribution centers are reducing forklift accidents, a major cause of injuries and death in factories.

Top Ten Benefits of Fork Truck Free with One Piece Flow and Small Lot: Delivery Improves Quality

Fork Truck Free Benefit: Builds in quality.

When utilizing one-piece flow and Fork Truck Free, every worker is an inspector. One Piece Flow refers to the concept of moving one workpiece at a time between operations within a work cell. The opposite activity is to process an entire batch or lot at each operation before moving it to the next operation.

One Piece Flow keeps WIP (work in process) at the lowest possible level, encouraging work balance, better quality, and other internal improvements. Each piece or lot is looked at by the next process (the customer) immediately, so defects are caught sooner. If defects are passed on, it is a very small batch.

One Piece Flow is a fundamental element of becoming lean. Processing one unit at a time may meet with resistance from manufacturing organization which live in the realm of batch manufacturing. The word “one” is not literal and may in fact be related to the customers’ requirements and could be one unit of order. In the lean construct, it does require a manufacturer to only process what the customer wants, in the quantity, and in the time needed.

Quantifying One Piece Flow, Quality and Fork Truck Free

By calculating the takt time for products all cycle times are either less than, or equal to, the takt time. This may involve many kaizen events to achieve but is essential. The starting point (current state of the Value Stream Map) will establish a benchmark to determine the efficacy of a future state which is Fork Truck Free.

Manufacturers must base the process capacity or equipment capacity on the takt time. This initiates a Kanban pull system of working.

Instead of fork trucks throughout the plant, One Piece Flow ensures that the layout of a manufacturing plant supports Fork Truck Free as a quality improvement. Each layer of cellular manufacturing can be measured against the target of defect-free. There is no value in allowing the defect to permeate downstream manufacturing. The cost of scrap materials from defective batch manufacturing often exceeds the profit margin to manufacture the product.

Top Ten Benefits of Fork Truck Free with One Piece Flow and Small Lot Delivery Improves Flexibility

One piece flow requires that production of the product moves from one stage to the next stage one piece at a time. Lot production is quite different and hampers flexibility because several units are made at a given stage and are then all are moved to the next stage at the same time. Most operational excellence practitioners promote one piece movement because it synchronizes effectively with just-in-time (JIT) production while eliminating idle time between the units. With lot production, the first piece made cannot move to the next step until the last piece in the lot is made. The result is lot production incurs waste as the first and subsequent product remains idle.

One piece flow comes from the Toyota Production System, the foundation of Lean Manufacturing. One piece flow is also known by various other names such as the following:

- Make-one, Move-one

- Single-piece Flow

- Continuous Flow

- Flow Manufacturing

As described above, the Toyota Production Systems emphasizes right-sizing production eliminating queues, which leads to waiting time, which leads to poor space or resource utilization, increased Work-in-Process (WIP), longer cycle times, which are all forms of waste and antithetical to lean.

Less inventory on the floor allows lead times to drop, which provides flexibility to product increased customer orders.

Recently, the EPA advocated for the flexibility found in cellular manufacturing, production work stations, and equipment because they are arranged in a sequence that supports a smooth flow of materials and components through the production process with minimal transport or delay. Implementation of this lean method often represents the first major shift in production activity, and it is the key enabler of increased production velocity and flexibility, as well as the reduction of capital requirements.

Rather than processing multiple parts before sending them on to the next machine or process step (as is the case in batch-and-queue, or large-lot production), cellular manufacturing aims to move products through the manufacturing process one-piece at a time, at a rate determined by customers’ needs.

Cellular manufacturing can also provide companies with the flexibility to vary product type or features on the production line in response to specific customer demands. The approach seeks to minimize the time it takes for a single product to flow through the entire production process.

The one piece flow method includes specific analytical techniques for assessing current operations and designing a new cell-based manufacturing layout that will shorten cycle times and changeover times. To make the cellular design work, an organization must often replace large, high volume production machines with small, flexible, “right-sized” machines to fit well in the cell. Equipment often must be modified to stop and signal when a cycle is complete or when problems occur, using a technique called automation (or jidoka).

This transformation often shifts worker responsibilities from watching a single machine, to managing multiple machines in a production cell. While plant-floor workers may need to feed or unload pieces at the beginning or end of the process sequence, they are generally freed to focus on implementing TPM (Total Productive Maintenance) and process improvements. Using this technique, production capacity can be incrementally increased or decreased by adding or removing production cells. Each of these flexible elements is best supported in a Fork Truck Free manufacturing production facility.

Top Ten Benefits of Fork Truck Free with One Piece Flow and Small Lot Delivery Improves Scalability

One-piece flow equipment can be designed smaller, slower (paced to takt time), and generally at lower costs. Rather than making a process fast as technically possible, often resulting in local optimization and batch processing, very simple processes can be used.

In manufacturing, one piece flow is where a single piece is placed between workstations. There is usually minor variance in each workers’ cycle time that does not cause any waiting time. Optimally there should be an exceptionally high cycle balance between operations because the greater the number of pieces in each operation, the greater the variation in cycle times from operation to operation. This can result in overproduction and requires knowledge when to decrease the buffer between operations and increase the losses due to work times that are imbalanced.

While not simple, because one piece flow can be addressed per work cell, it is truly scalable. As mastery is achieved, it can be expanded to other work cells and eventually enterprise-wide.

Consistent capability requires consistent availability and application of resources including, but not limited to, people, equipment, and materials. One piece flow can be unsuccessful without consistent availability of these resources. Fork Truck Free trains of industrial carts can be a significant part of creating a methodology ensuring all materials are at the right work station at the right time with the right labor.

Achieving improved scalability from one piece flow is achieved with accurate takt time quantification. “Dynamic Lean Assessment for Takt Time Implementation” authors, Ahmed and Deif suggested that due to increasing volatility, global competitiveness, and sales crises, manufacturers are forced to commit to the journey of world-class manufacturing performance via adopting “lean systems” to enable economic success.

Ahmed and Deif argued that the journey to lean is one of the hardest steps in measuring the progress of lean policy. The model is based on system dynamics approach and presents a “leanness score” for the manufacturing system. In addition, it examines the dynamics associated with the application of “one-piece flow” concept via “takt time.” Results show that working on adjusting the system’s cycle times to follow takt time will improve the overall performance. Improvements are reflected in the overall service level, overall WIP efficiency, and overall equipment effectiveness. Only with these performance metrics, one piece flow and the utilization of Fork Truck Free solutions, will decision-makers adopt different lean policies and assist in optimal parameters settings of the system.

Top Ten Benefits of Fork Truck Free with One Piece Flow and Small Lot Delivery Reduces Inventory

One Piece Flow and Fork Truck Free Reduces Carrying Costs

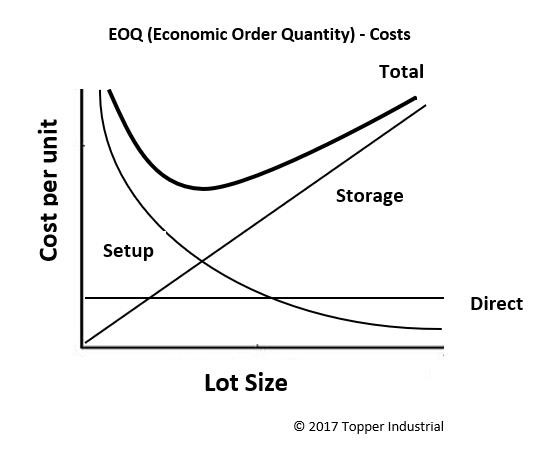

Carrying or Storage cost is the average cost associated with storing an average production unit for the average time it will be in inventory. Storage costs are significant and often represent 20-60 percent of inventory value on an annual basis.

Carrying Cost per piece varies directly with batch quantity. The larger the batch, the more units will be in inventory.

Quantifying One Piece Flow and Fork Truck Free Reduces Inventory

Inventory management plays a crucial role in balancing the benefits and disadvantages associated with holding inventory. Efficient and effective inventory reduction strategies go a long way in the successful running and survival of a manufacturer or distributor.

Inventory comprises an important part of current assets, particularly in manufacturing industry. A lot of cash flow is committed to inventories; ensuring a smooth flow of production to meet a demanding customer service level is the capacity to deliver product on time. That said, maintaining inventory also involves holding or carrying costs along with opportunity cost. Identifying inventory reduction strategies becomes critical for supply chain and operations professionals.

Using Pareto ABC analysis will help determine which inventory is used most often. In very simple terms “A” is the inventory that is used the most, “B” is the product that is important yet used less frequently, and “C” are the products that are rarely used. “A” classification products are used frequently and can be ordered in a small quantity, or be delivered Just in time (JIT) and will require less safety stock, and “C” products can be ordered less frequently but with more safety stock kept.

Safety stock is used to absorb lead-time variation and demand variation of customer demand and achieve required service level (95 percent in in most cases). Maintaining and reviewing the correct safety stock levels are needed to achieve the right customer service levels and market lead times.

Material flow and the fork truck free environment ensures that inventory levels are reduced and allow savings on costs, decreased lost profit (eliminating carry costs), and free up money for other business operations. Too often inventory is so over saturated that a bulk of it becomes obsolete before it can be sold. When customer demand is forecasted incorrectly, unsold inventory accumulates.

Lean inventory control via one piece flow can be found in the cap of work in process (WIP). In-process cycle times and lead times drop and as a result inventory shrinks, quality rises with the adoption of this process.

Standardizing parts can greatly reduce part inventory to only the standard parts, which can then be “ordered” as a steady flow, with the confidence that they will be used. With enough standardization, the standard parts can even have a small stock on hand to even out product demand

One piece flow and continuous improvement (kaizen) are inter-dependent. Manufacturers often hide behind inventory pretending they are utilizing one piece flow. In fact, it is an artificial flow has characteristics, such as moving equipment close together to create what looks like a one piece flow cell, then batching product at each stage with no sense of customer takt time. It looks like a cell, but it works like a batch process.

Top Ten Benefits of Fork Truck Free with One Piece Flow and Small Lot Delivery Improves Productivity

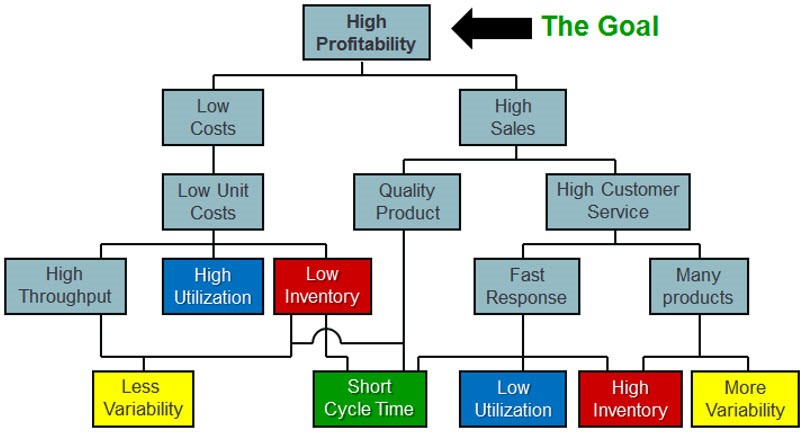

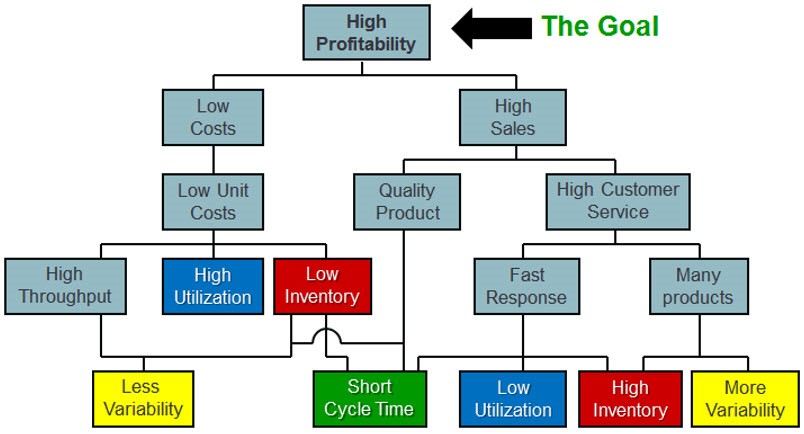

Productivity is the efficiency with which a manufacturer converts inputs into outputs. Since staff represent the largest cost for many firms, labor productivity has special importance and vitally affecting competitiveness.

Manufacturers with higher productivity charge lower prices or increase profit margin (or choose a combination of the two). Improved productivity must never compromise production quality.

Training can improve the knowledge and skills of staff, yet investment in equipment and new technology most often enables output per worker to increase.

Improved productivity should also be quantified by plant and machinery effectiveness. When a machine might be available and functioning normally for 80 percent of an average week, there is lost productivity even during cleaning and repair. The production manager may consider that this figure could be improved through better and more regular servicing.

Measuring the productivity of capital is frequently calculated by the return on capital employed. Maximizing uptime and throughput to protect profit margins start with a clear VSM (Value Stream Map). Identifying current process inefficiencies create a great starting point. Industrial carts in the Fork Truck Free environment along with one piece flow produce intuitive handling impacts, while considering the ergonomic setup options minimizing operator fatigue to speed up production. Measuring results can be integrated into best-practices triggering a process step to improve throughput.

Batching is not always bad

There are situations where batch manufacturing is more cost-effective because of limitations resulting from tooling, equipment, technology, or process design. Although producing work in batches under these circumstances may be the most logical and cost-effective choice today, it should never be considered acceptable into the future. Batching must be considered a countermeasure until the process can be improved one piece flow (or smaller batches) occurs.

It is important to understand the effect that batching has on process flow, operating costs, and overall competitiveness and productivity of the manufacturer. It requires a deep understanding of the process and the needs of the customer.

The waste in Batch Process prove it is not lean

Eliminating waste is the heart and soul of lean manufacturing. One piece flow avoids the frequent sources of waste resulting from batching processing. It makes no sense to increase the time between spending money in a process and receiving money from customers due to an increased overall cycle time. It makes no sense to create inventory that is not yet sold.

Direct waste can be quantified in waiting and downtime in one or more steps of the process while previous steps complete work on multiple units and larger amounts of inventory between process steps.

Batching guarantees that one step will shut down while waiting for a previous step to complete a batch, and increased rework and delays will occur when a defect is discovered. Importantly, one piece flow will immediately highlight any problems with vendors, often the source of productivity hemorrhaging.

Top Ten Benefits of Fork Truck Free with One Piece Flow and Small Lot Delivery Simplifies Material Replenishment

Material replenishment is a real challenge for manufacturers. The fork truck free utilization requires that materials are staged for as little down time as possible. One piece flow and small lot delivery allows for a far more precise calculation of material replenishment. All manufacturing processes are not equal, and some processes are identified best-suited to one piece flow.

Rate-base or Just-in-time involves forecasting of the flow rate or takt time. RCCP – rough cut capacity planning monitors impact of mix and volume. The differentiation is the manufacturing process is either produced to rate (TAKT) rather than discrete orders or customer pull. Material replenishment is distinct based on demand flow versus time-phased requirements planning. The challenge is maintaining flow priority and timing, best accomplished via one-piece flow, zero inventory, standard WIP – work-in-process. The advantage of seamless flow/pull of material is capped off with dynamic cycle time, also known as Little’s Law.

Little’s Law calculates the average waiting time and the average number of items waiting for a product or service. This fundamental law has found numerous uses in operations management and managerial decision making.

Pull-based materials replenishment

The combination of discrete forecasting and/or demand rate-based forecasting is often characterized by MRP planning — pull Kanban, Heijunka visual shop floor control. The orders are flat Bills of Materials, more often cellular manufacturing, and point-of-use rather than central stores.

In this environment, inventory is strategic: standard inventory, time-based replenishment, pull based on consumption vs. push based on demand. The inventory management is based on statistically balanced rate, build to level-loaded demand with calculated standard inventory buffers.

Push or Job Shop Discrete

Discrete requirements planning (firm orders and long-range forecast) allow for a Rough Cut Capacity Plan (RCCP) and timed phasing of requirements, application of order policies: lead time, and safety stock. This process is based more heavily in Capacity Requirements Planning with the ability to aggregate disparate requirements across multiple products by work center, supplier, and products. This methodology is batch processing, not one piece material flow, and has multi-level inventory with stores, picks, kits, move, and queue as the manufacturing steps. This is the least lean manufacturing process because demand leveling is difficult and not at all economical.

The Cornerstone of Lean Founding in Simplified Materials Handling

Point of Use replenishment is the foundation of lean and fundamental in the elimination of waste. Ensuring that materials are available to workers exactly when, where, and as needed, help to eliminate wasted movement, time, and excess inventory.

One piece material flow delivered by a fork truck free work environment support a myriad of replenishment methodologies and system designs to help manufacturers on continuous process improvement. Working with buyers, planners, line leads, and other personnel to map the most efficient supply system for each value streams or production lines assures simplified materials handling.

Top Ten Benefits of Fork Truck Free with One Piece Flow and Small Lot Delivery Frees Up Floor Space

One of the lost financially quantifiable impacts of one piece flow and small lot delivery is freeing up floor space. Because single piece flow naturally works within a cell, there is less space for the accumulation of inventory between processes. A cell is setup to maximize production floor space and improve communication between processes to improve quality and increase throughput. There is no waste associated with defects, scrap, unneeded stacks of raw material, or stacks of finished goods waiting for the next process. None of those costly elements exists because as soon as inventory is created (in the form of one unit), it is absorbed and processed by the next station and so on, down through the line.

Batched parts occupy much more space than a single piece flow, especially if batches are so heavy that forklift aisles are needed. Eliminating fork trucks can drive a space savings up to 30 percent of a manufacturing plant floor.

Companies anticipating expansion or new plants discover that in the fork truck free environment, current manufacturing facilities are often more than adequate.

If setup can be eliminated or reduced, the need to manufacture in batches, then parts, sub-assemblies, and products can flow one piece at a time. One piece flow may be essential when building to-order a wide variety of standard or mass-customized products. It also eliminates much of the waste of batch-and-queue manufacturing: waiting, interruptions, overproduction, extra handling, recurring defects, and other non-value-added activities.

Lean Implementation

There is a myriad of benefits of a lean implementation resulting in one piece flow, small lot delivery, and the fork truck free benefits. A safer workplace with defects reduced by 30 percent or more are often the result. Quality costs improvements increase up to 50 percent with delivery lead times reduced by more than 50 percent.

On Time Delivery Improved to 99+ Percent

With inventory (working capital) reductions of more than 50 percent and optimized equipment (capital equipment utilized for direct production and support) the ROI of the implementation of lean is rather simple to accomplish.

Most manufacturers report between a 30 to 50 percent reduction in floor space requirements while achieving a return on assets improvement of 99+ percent. A competitive world class manufacturing operation starts in a Fork Truck Free Lean Manufacturing Environment.

Top Ten Benefits of Fork Truck Free with One Piece Flow and Small Lot Delivery Makes Kaizen Take Root

Lean leadership is required for any program to become part of the culture. Whether prompted by Theory of Constraints, Lean Six Sigma, or Lean manufacturing principles top down leadership enrolling the entire team is essential. This is proven because when the leaders leave, the lean culture often retreats to doing things the “old way.”

Because the simplest behavior of lean culture, continuous process improvement, is a kaizen event, one piece flow and small lot repetitive delivery allow kaizen events to take root. It does not require a gemba walk throughout the whole plant. A single manufacturing cell that has material on time to build for a specific order is either working or failing.

Failures don’t happen over time with one piece flow. The second order is held up because of product defect discovered in the first assembly process. Corrective action is mandated before the second order commences.

Sometimes referred to as “single piece flow” or “continuous flow,” one piece flow is a key concept within the Toyota Production System. Achieving one piece flow helps manufacturers achieve true just-in-time manufacturing. When the right parts can be made available when they are needed in the quantity they are needed, it becomes evident that Kaizen events have taken root to the company culture.

One piece flow means that parts are moved through operations from step-to-step with no WIP (work in process) in between either one piece at a time or a small batch at a time. This system works best in combination with a cellular layout in which all necessary equipment is located within a cell in the sequence in which it is used. While many are familiar with the terminology, there is still a significant challenge in achieving it.

The Kaizen event creates the basis for a functional layout. The concept of achieving connected flow means implementing a means of connecting each process step within a value stream. In a typical MRP batch and queue manufacturing environment, parts move from functional area to functional area in batches, and each processing step or set of processing steps is controlled independently by a schedule. There is little relationship between each manufacturing step and the steps immediately upstream or downstream.

This is anathema to lean manufacturing because large amounts of scrap occurs when a defect is found because of large batches of WIP; also long manufacturing lead times occur driving poor on-time delivery and/or lots of finished goods inventory to compensate.

When we achieve connected flow, there is a relationship between processing steps. This type of system is Kaizen driven and creates a relationship with a pull-based system. One piece flow is the ideal method for creating connected flow because product is moved from step-to-step with essentially no waiting (zero WIP).

Ensuring all materials are where and when needed is best achieved in a fork truck free environment. Gemba walks and routine kaizen events continuously examine if there is a delay or less than optimal lean outcome. While lean leadership starts at the top, all stakeholders must see the material value of the effort. When everyone walks the kaizen path the efficacy and buy-in is widely adopted, understood, and part of lean company practice.

About Topper Industrial

For more than twenty years, Topper Industrial, (www.TopperIndustrial.com) based just outside of Milwaukee, WI, has been a leader in the material handling equipment industry. The company’s product roster features industrial carts, conveyors, lifts, lifts & tilts, shipping racks, containers, casters, and cart components. From mother-daughter carts to quad steer carts to tilt carts and rotate carts, Topper’s material handling solutions make delivering material line side more effective through more efficient practices. Topper Industrial has a team of experienced professional experts able to assess and provide the right product for all material handling equipment requirements.

Topper Industrial is a proud member of MHI. Follow on Twitter @TopperInd.