MRO stands for maintenance, repair, and operations. In procurement terms, it refers to the products and tools purchased that keep an organization running. MRO is also a way to turn spare parts into an opportunity for continuous improvement.

The three main types of maintenance that fall under MRO include:

Preventive Maintenance — This type of maintenance is done regularly before issues arise in order to keep equipment and processes running smoothly.

Corrective Maintenance — This refers to maintenance completed after a problem has occurred, whether dealing with general wear and tear or a complete breakdown.

Predictive Maintenance — Predictive maintenance is done based on the data obtained from monitoring processes that track historical trends, allowing for reliable failure predictions.

Normal wear and tear of fork truck free equipment dictates that parts eventually fail. Being prepared and having a plan to remedy the issue is important to minimize downtime. Parts management extends beyond simply replacing a broken part. Focusing on improving the reliability of every component and the piece of equipment allows leading-edge manufacturers to capture and analyze the data and understand what can be done to prevent downtime and labor costs in the future.

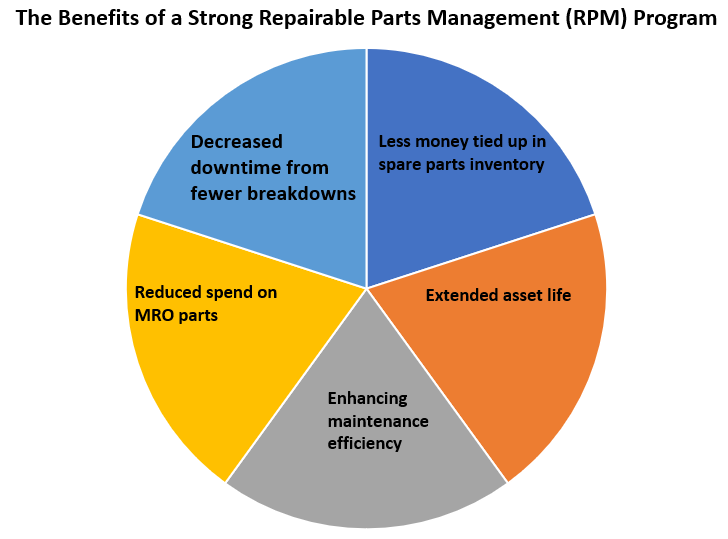

Having a strong repairable parts management (RPM) program is essential to manufacturing efficiency, extending the longevity of assets and increasing the productivity of equipment. Repairable parts management plans from Topper Industrial, delivers strategic on-site management – proactively eliminating waste, reducing costs, improving component reliability, and optimizing manufacturing performance.

Whether implemented as a standalone program or as part of an Asset Management Solution, Topper’s RPM program will measurably impact on MRO parts inventory management. Spare and replacement parts spending will fall, and component life will be extended. Overall equipment effectiveness (OEE) will increase, freeing maintenance resources for more proactive efforts. Realized savings throughout the manufacturing process provides end-to-end performance benefits.

Improve Work Order Management

From scheduling, dispatching, and mobility, the RPM defines job requirements and performs robust data which enables dispatchers to easily assign jobs to maintenance workers, with the associated assets, parts, tasks, estimation of processing and repair capabilities, driving customer satisfaction rates.

Using predictive logic, the Topper plan informs manufacturers how to budget for future maintenance programs, increasing revenue and future customer satisfaction. Predictive logic, plan part requirements, and monitor part utilization, ensures adequate stock to decrease downtime, failure rates, and labor costs.

Many manufacturers take these data and integrate them with asset and inventory management solutions which offer workorder management, Gantt scheduling interface, inventory management, including locations and shipments.

About Topper Industrial

For more than twenty years, Topper Industrial, (www.TopperIndustrial.com) based just outside of Milwaukee, WI, has been a leader in the material handling equipment industry. The company’s product roster features industrial carts, conveyors, lifts, lifts & tilts, shipping racks, containers, casters, and cart components. From mother-daughter carts to quad steer carts to tilt carts and rotate carts, Topper’s material handling solutions make delivering material line side more effective through more efficient practices. Topper Industrial has a team of experienced professional experts able to assess and provide the right product for all material handling equipment requirements.

Topper Industrial is a proud member of MHI. The Topper Industrial client roster includes Anderson Windows, Detroit Diesel, Honda, Kia Motors, Ford, Chrysler, Aramark, Johnson Controls, Whirlpool, and Caterpillar. Follow on Twitter @TopperInd. Call 800-529-0909.

Media Contact: Jillian Burrow / pr@topperindustrial.com / 1-800-529-0909