Kevin G. Owens, Product Liability Attorney, Johnson & Bell, Ltd., noted that risk assessment is an essential business process. Owens added that risk assessment allows manufacturers to protect something of value… product quality, productivity, and workers. It is an essential tool for machine safety and is required by safety standards in the U.S. and Europe through the machinery directive.

In a recent event hosted by Owens, co-presenter Bruce Main, President of Design Safety Engineering, Inc., shared how important it is for manufacturers to gain a good working knowledge of the risk assessment process and how it can be used to address product safety and machine safety issues. Risk assessment can be used throughout a business from management to the factory floor. In many industries, line workers use risk assessment to address safety issues as part of continuous improvement.

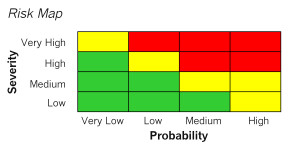

The Risk Map was presented during the event.

Main reviewed some of the key issues to ask including…

- What is risk assessment and where did it originate?

- How to use risk assessment for machine safety and product safety?

- What is acceptable risk – when are you finished with a risk assessment?

- The legal implications of risk assessment

- How risk assessment can increase product quality, productivity and improve worker safety

- Upgrading Legacy Safety Technologies

A Safer, More Productive Manufacturing Operation

OSHA’s Office of Regulatory Affairs suggested that $4-6 is saved for every $1 invested in safety equipment and programs. Topper Industrial’s focus is on preventing the impact an accident can have on operations. Beyond the obvious and unacceptable emotional cost to employees, the direct and indirect costs of an accident – from workers’ compensation benefits and lost productivity to damaged goods and machinery – can accelerate quickly.

There are webinars, events, and copious discussions of compliance to applicable standards; reducing machine operator risk; protecting capital equipment; safety components; architecting a safety solution and establishing integration protocols. These are all fine, but feeble attempts to permanently reduce the probability and severity of risk.

The single biggest risk on the manufacturing plant floor is the forklift.

Only in a fork truck free environment can the severity and probability of worker injury be dramatically mitigated. Automated solutions that are ergonomically desirable, cost-effective, (industrial carts are leased at less than $100 per cart per month) and pull by automated tuggers rather than fork trucks, prove safer and more profitable.

Risk assessment leads to risk management. Risk management mandates a fork truck free environment.

Posted by Jillian Burrow, Marketing Manager for Topper Industrial – Material Handling Solutions

No Comments Yet!

You can be first to comment this post!